Model Description:

n The HMR type is equipped with an internal and external flushing structure, and can also be used without internal flushing or external flushing depending on the situation

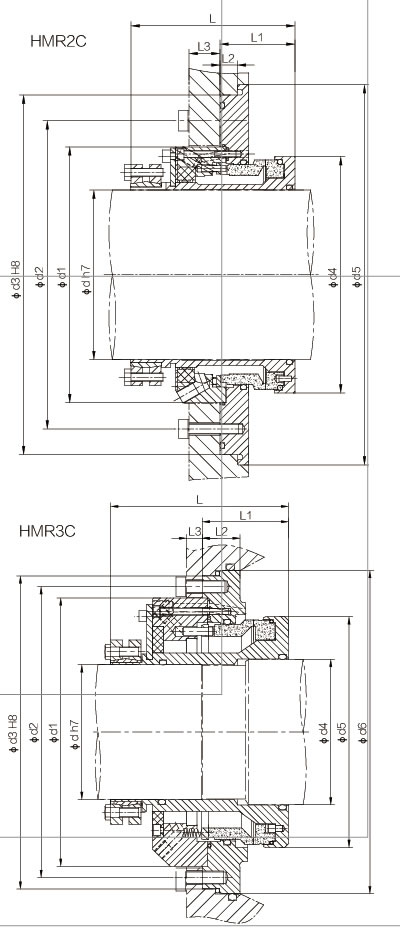

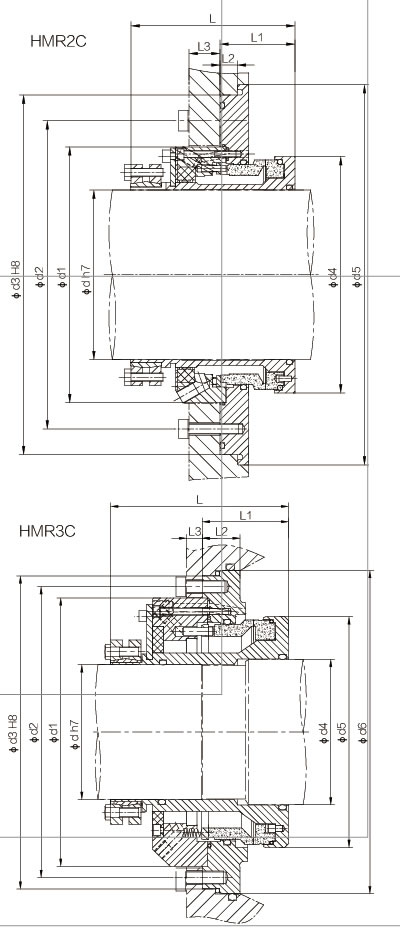

n The inner hole of HMR2 type shaft sleeve is a through-hole

n The inner hole of the HMR3 type shaft sleeve is a stepped hole, and the connecting flange is equipped with a static ring protection protrusion

Structural characteristics:

n Single end containerized mechanical seal

n Balanced type

n Static loop compensation

n Spring and medium isolation

n The connecting flange is installed inside the pump chamber

Parameter Range:

n Pressure: 0-0.8MPa

n Temperature: -20~120 ℃

n Linear velocity: ≤ 10m/s

n Solid content: ≤ 18%

n The allowable axial displacement is ± 0.3mm

n Shaft diameter: 30-220mm

Lubrication and cooling

n Lubrication and cooling by medium or external rapid cooling fluid

n The pressure of the flushing fluid should be less than 0.05 MPa, and it should be able to maintain flow

n The pressure of the internal flushing water should be 0.1-0.3 MPa higher than the pressure of the medium inside the sealed chamber

Application conditions:

It can completely replace the mechanical seals imported from KSB pumps and WARMAN pumps used in power plant flue gas desulfurization devices, and is also used in slurry circulation pumps produced by domestic manufacturers such as Xiangyang 525 Pump Industry Co., Ltd., Shijiazhuang Industrial Pump Factory Co., Ltd., and Shijiazhuang Qianqiang Pump Industry Group.